Rway – your right way of electronic realization!

Better, Quicker, Cheaper!

All under one roof with a single accountable electronics manufacturer.

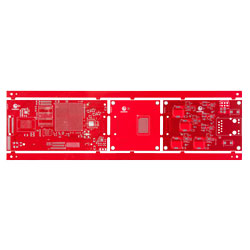

Turn Times

- Same day – 4 weeks

- Scheduled deliveries

Volume

- No minimum order quantity

- Engineering prototypes

- Low cost first article builds

Parts Procurement

- Turnkey

- Kitted/Consigned

- Partial Turnkey

Stencils

- Laser cut stainless steel

- Nano-coating available

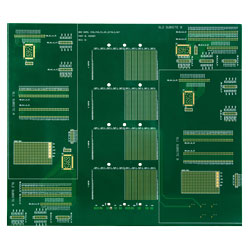

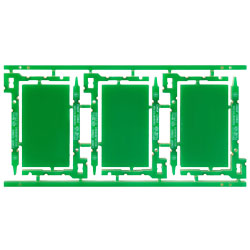

Assembly Types

- Surface Mount(SMT)

- Through-hole(THT)

- Mixed Technology(SMT/THT)

- Single/double sided placement

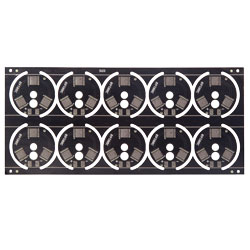

Passive Components

- As small as 0402 package

- As small as 0201 with design review

Solder Types

- Leaded

- Lead-free/RoHS compliant

- No-clean process available

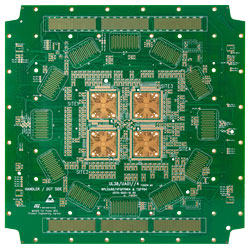

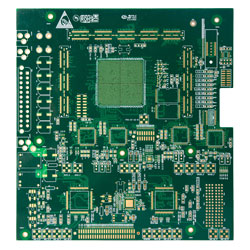

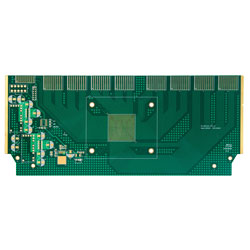

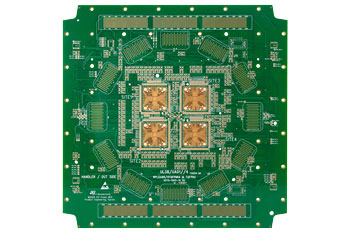

Ball Grid Arrays (BGA)

- As small as .35mm pitch

- x-ray inspection

Fine Pitch Components

- As small as 15 mil pitch

Other Capabilities

- Repair/Rework services

- Mechanical Assembly

- Electromechanical Assembly

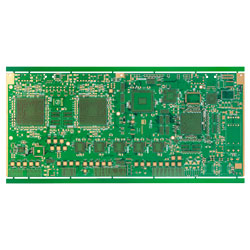

Quality comes as standard – at Rway every PCB and electronic assembly is produced under the control of our ISO9001 quality management system, all electronic manufacturing is in accordance with IPC acceptability standards, and all workmanship is qualified to IPC-A-600 (for acceptance of printed circuit boards) & IPC-A-610 (acceptability of electronic assemblies), we take the greatest care to ensure that your product is manufactured and tested to the highest possible standard. By utilizing proven quality control procedures we always aim to exceed your expectations.

Quality comes as standard – at Rway every PCB and electronic assembly is produced under the control of our ISO9001 quality management system, all electronic manufacturing is in accordance with IPC acceptability standards, and all workmanship is qualified to IPC-A-600 (for acceptance of printed circuit boards) & IPC-A-610 (acceptability of electronic assemblies), we take the greatest care to ensure that your product is manufactured and tested to the highest possible standard. By utilizing proven quality control procedures we always aim to exceed your expectations.

Having been in the industry for about 10 years, we understand the importance of production timescales, so we will provide you with a detailed build schedule from production to packaging, and this can be as flexible as you need with your delivery options.

Having been in the industry for about 10 years, we understand the importance of production timescales, so we will provide you with a detailed build schedule from production to packaging, and this can be as flexible as you need with your delivery options.

Our pricing is competitive, reasonable and affordable, having no hidden cost in it, at it we offer the best combination of customer service and product performance, ensuring the highest level of quality to be met, plus, we always seek to help customers reduce/save cost by using the latest technology, newest methodology, and effectively optimizing the manufacturing processes.

Our pricing is competitive, reasonable and affordable, having no hidden cost in it, at it we offer the best combination of customer service and product performance, ensuring the highest level of quality to be met, plus, we always seek to help customers reduce/save cost by using the latest technology, newest methodology, and effectively optimizing the manufacturing processes.

We have a very strong base for customer support, which means our response to customers’ inquiry(no matter it is to quote or order status) is very quick, effective, our sales force are trained to be customer-oriented, passionate and professional, they can work with customers very collaboratively to solve problems that arise, besides, we offer one-stop service ranging from quick-turn PCB prototype to complex end products, it is scalable, flexible that customers can choose what they want.

We have a very strong base for customer support, which means our response to customers’ inquiry(no matter it is to quote or order status) is very quick, effective, our sales force are trained to be customer-oriented, passionate and professional, they can work with customers very collaboratively to solve problems that arise, besides, we offer one-stop service ranging from quick-turn PCB prototype to complex end products, it is scalable, flexible that customers can choose what they want.

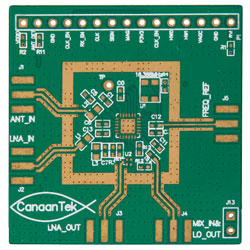

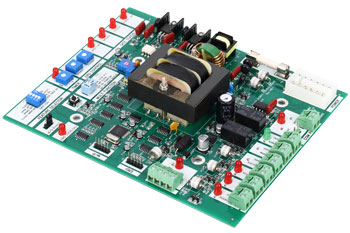

Rway uses the latest pick & place technology from JUKI to produce reliable PCBAs quickly and precisely.

Rway sources parts from well-known distributors to ensure consistent quality and reliability of your end products.

Rway’s services and products are widely approved by customers.

“Received the boards, wonderfully packaged, found really good for the price. I tested only some of them, and, of course, they are perfect. Thank you very much for your good service.“

“I’ve tested/assembled half of them. So far 100% pass rate. I’ve been building these for 5 years, you’re the 4th assembler i’ve used, no one has ever hit 100% before. Nice job. Please pass along my thanks and regards to your team.“

“The boards you assembled for us have been functioning very reliably, we are very satisfied with their quality, thank you for your good work, i am sure we will come to you again for other projects soon.“

Find out how we can help you succeed the first time, in record time!

Our services are customized to your needs and we will consult with you as often as required to ensure your satisfaction.